Advancing Pipe Cutting Safety & Efficiency in NSW Utility Infrastructure

Pipe replacement, maintenance, and emergency repairs within the NSW water and sewer network frequently occur under constrained and high-risk conditions. Operators are often required to cut ductile iron, reinforced concrete, or composite pipe within:

Narrow trenches

Confined service corridors

High-moisture or flooded environments

Live infrastructure zones with restricted ventilation

Under these conditions, traditional petrol-powered cut-off saws introduce several compounding risk factors: exhaust emissions within the trench, elevated vibration and fatigue from engine weight, higher acoustic exposure, and increased reactive forces during blade binding.

As safety frameworks within state water authorities continue to evolve toward stricter confined space and environmental standards, the suitability of combustion-driven cutting equipment is increasingly being scrutinised.

HYCON Australia is currently working alongside a major end user within the NSW state water network to progress the approval of hydraulic-powered cutting systems specifically the HYCON hydraulic ring saw and power pack platform — for use across utility-controlled sites.

Technical Overview: Hydraulic Power in Utility Applications

Hydraulic systems operate as closed-loop circuits powered by an external hydraulic power pack or excavator hydraulic supply.

From an engineering standpoint, this architecture separates the combustion source from the cutting interface. The implications are significant:

No exhaust gases generated at the point of cutting

Reduced heat signature within confined spaces

Lower operator exposure to airborne contaminants

Reduced acoustic intensity within the trench

The hydraulic power pack used in the HYCON system produces a sound power level of approximately 109 dB, compared to approximately 115 dB typical of petrol-powered cut-off saw engines.

In practical terms, this reduces peak acoustic energy at operator level and improves overall site compliance capability.

Hydraulic tools also provide one of the highest power-to-weight ratios among portable cutting systems, resulting in lighter handheld tools with reduced static load and improved handling characteristics.

The HYCON Hydraulic Ring Saw: Engineering Advantages

The HYCON Hydraulic Ring Saw has been specifically engineered to provide deep cutting capability while mitigating common reactive forces associated with traditional cut-off saws.

Unlike conventional centre-driven cut-off saws, the ring saw utilises a peripheral drive system. Drive rollers engage the blade at its outer diameter rather than through a central arbor.

This configuration delivers two critical advantages:

Greater Depth of Cut Relative to Blade Diameter

A 16-inch ring saw blade achieves up to 300mm (11.8”) cutting depth.

This allows operators to complete cuts in pipe diameters up to approximately 10 inches from a single cutting position.

Reduced Excavation Requirement

Because the tool does not require rotation around the pipe to complete the cut, clearance excavation is significantly reduced. This minimises trench enlargement and reduces reinstatement effort.

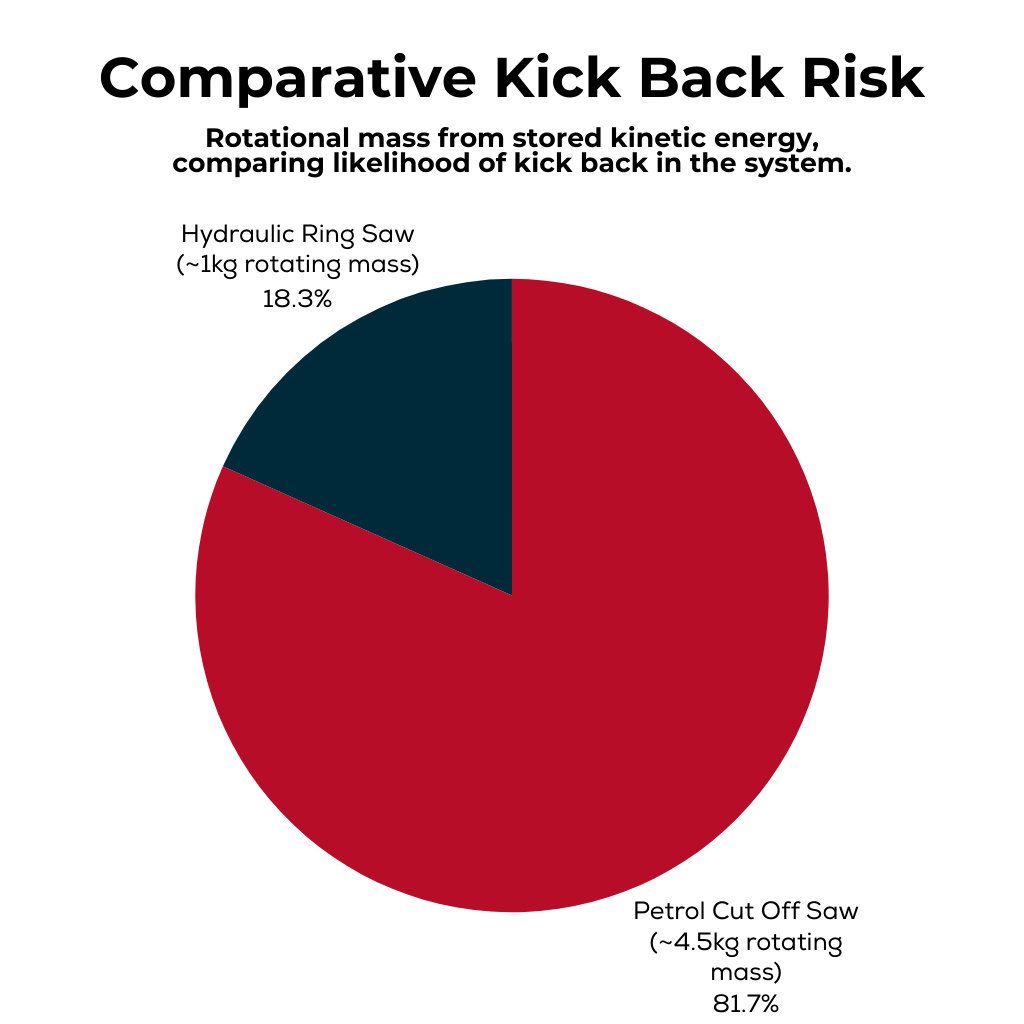

Rotational Energy & Kickback Mitigation

From a mechanical safety perspective, one of the most significant differentiators between hydraulic ring saws and petrol cut-off saws lies in blade mass and rotational inertia. A 16-inch ring saw blade with 300mm cutting depth weighs approximately 1kg. By comparison, a 20-inch petrol cut-off disc delivering only 212mm cutting depth can weigh approximately 4.5kg. The stored rotational energy in a rotating system is directly proportional to its mass and square of its velocity. Reduced blade mass and lower operating RPM in the hydraulic ring saw significantly decrease kinetic energy within the system.

In practical trench cutting scenarios — particularly when cutting below pipe centreline — this translates to:

Reduced severity of kickback events

Lower torque reaction during blade binding

Improved operator control under variable load conditions

Furthermore, the HYCON ring saw incorporates two additional mechanical safeguards:

Peripheral Drive Friction Interface

The drive rollers function analogously to a friction clutch. If the blade binds, controlled slippage occurs rather than instantaneous mechanical lock-up.

Integrated Pressure Relief Valve

In the event of blade jamming, hydraulic flow is automatically bypassed back to tank, preventing sudden re-engagement forces.

This layered approach to reactive force mitigation provides a measurable improvement in operational control compared to petrol-driven systems.

Environmental & Confined Space Considerations

Utility pipe cutting often occurs within trenches that may exceed 1.5m in depth, where natural ventilation is minimal.

Petrol-powered saws place a two-stroke or four-stroke combustion engine directly within the trench environment. Two-stroke engines, in particular, introduce additional particulate and hydrocarbon emissions due to oil-fuel mixture combustion.

Hydraulic systems eliminate this exposure entirely at the cutting location

For water authorities increasingly focused on:

Worker exposure minimisation

Environmental compliance

Emissions reduction

Confined space risk controls

Hydraulic cutting technology provides a structurally superior approach.

Application Scope Within Utility Networks

For pipes up to approximately 10” diameter, the hydraulic ring saw provides optimal balance between:

Cutting capacity

Excavation minimisation

Safety performance

Operator ergonomics

For larger diameters exceeding 10”, the HYCON HPS hydraulic chain saw offers extended reach capability while retaining the same hydraulic safety advantages.

All systems can be powered via:

Standalone hydraulic power packs

Hydraulic outputs from excavators

Shared hydraulic platforms on utility service vehicles

This platform flexibility enables integration into existing utility fleet infrastructure without extensive capital restructuring.

Strategic Implications for NSW Water Authorities

The transition from petrol-powered to hydraulic cutting systems is not merely a tooling upgrade — it represents a broader shift toward safer trench operations and improved compliance positioning.

By progressing approval of HYCON hydraulic systems within NSW state water networks, APG Australia is supporting:

Reduced reactive force exposure

Improved confined space conditions

Lower acoustic and emission impact

Standardised hydraulic platform compatibility

Once authority-level approval is achieved, subcontractor adoption pathways are significantly streamlined, supporting consistent safety standards across tier-one and tier-two contractors.

Hydraulic ring saw technology provides a technically superior alternative to traditional petrol-powered cut-off saws in trench-based utility pipe cutting.

Through reduced rotational mass, remote power source architecture, integrated hydraulic safety systems, and deep cutting capability from a single position, the HYCON Hydraulic Ring Saw aligns with the operational, safety, and environmental priorities of modern Australian utility providers.

For NSW water infrastructure projects, hydraulic cutting represents not only an advancement in performance — but a measurable improvement in trench safety management.